Industry Solutions

Automotive Components Inspection

A headlight, a suspension part, a wheel rim, a bumper or a plastic air filter box; every automotive component has its own dimensional specifications. Leader Metrology offers various CMM supporting touch trigger, analog scanning and laser scanning measurement, which can be executed in operating quick inspection checks on the shop floor or near the production machine.

Trim parts used as part of vehicle interior set specific quality control challenges. RationalDMIS measuring software yields accurate and repeatable results because it is allowing a part’s contours and geometric features of to be evaluated thoroughly.

Focus graphic CAD comparison charts provide powerful insight into local surface deviation, resulting in fewer iteration steps.

Sheet Metal Inspection

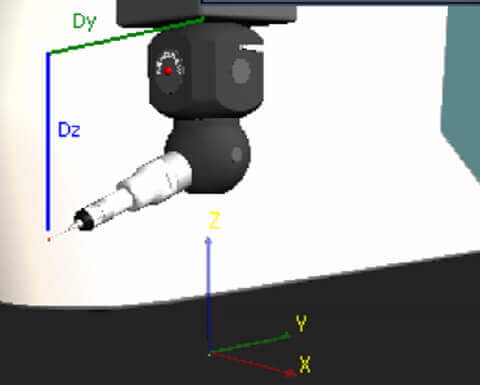

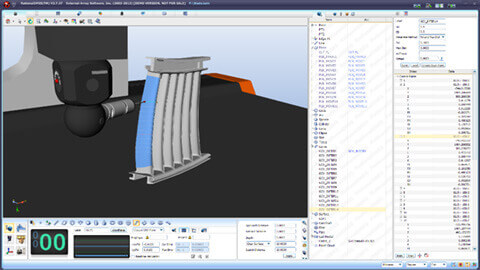

Stamping and bending allows sheet metal to be produced according to any desired freeform shape. The shape of the mating surfaces is important to obtain a good fit between assembled parts. To ensure that geometry specifications are actually met, freeform surfaces can be verified using touch sensors. Leader CMMs equipped with a variety of sensors, even including the fully integrated 5-axis REVO head for continuous touch probe scanning. It can quickly measure the entire shape and graphically highlight CAD deviations and surface irregularities, and eliminating potential anomalies.

Aircraft Component Inspection

Leader Metrology offers truly flexible and reliable gantry CMMs. In addition to high accuracy with maximum volume, gantry CMMs support a variety of probing solutions, including touch-trigger and laser scanning sensors.

For supersize fuselage, wing or engine parts, leading aircraft manufacturers count on laser scanning probe system, which can offer accurate and contactless inspection capabilities that are used within a wide variety of large volume measurement and inspection applications.

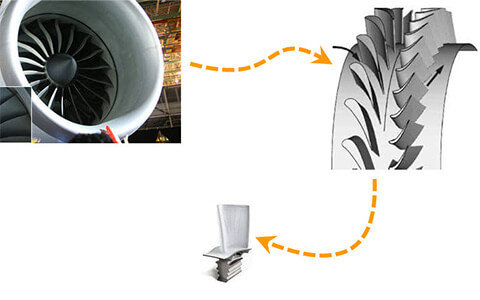

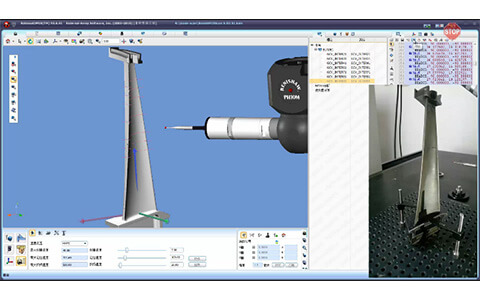

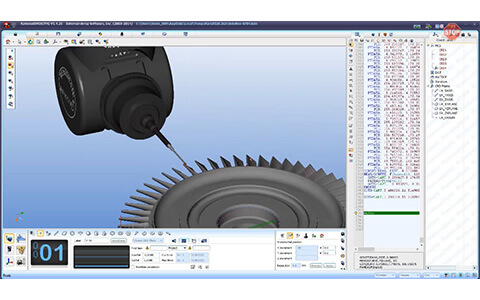

Turbine Blades Inspection

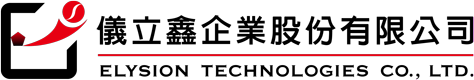

Traditionally, turbine blades or film radiography are verified through touch sensors based CMM inspection. However, blade manufacturers increasingly use laser scanning to verify the shape of the aerodynamic blade surface and the dimensions of milled planes and flanges, drilled holes and alignment notches.

Compared to traditional tactile inspection, SP25M laser scanning probe system captures much more point data in a shorter time frame, and embeds measurement and analysis in an automatic digital inspection process. At the same time, non-contact measurement requires little or no blade pre-alignment, and eliminates probe compensation when scanning freeform blade surfaces. By capturing thousands of inspection points per second, Focus software is able to apply far more accurate line fitting to determine the positions of notch edges and verify the angles between notches. Laser scanning and Focus point cloud processing software are the cornerstones of a much faster and operator-independent digital inspection process.

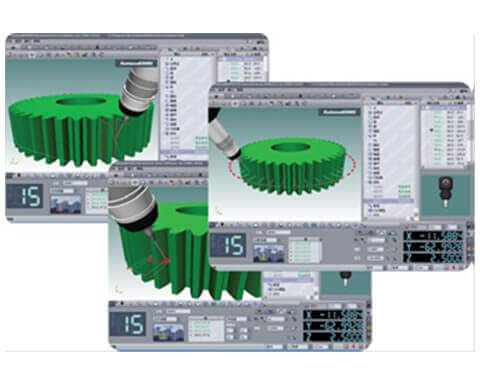

Specialty Modules Measurement

Used to measure various gear configurations including internal straight gears, external straight gears and helical gears.Gear measurement is easy and intuitive through the simple input of gear nominal parameters, and intelligent dynamic 3D model construction. This eliminates the time and cost associated with the creation of CAD for gears and the ease of use offers a savings cost through improved efficiency. The evaluation of gear path, lead, profile and run-out tolerances are readily supported.

Wine Turbines

The high tolerances for dimension, shape and position of movable components for wind turbines must be adhered to precisely. Therefore, the Leader CMM is the right choice. The highly precise and dynamic coordinate measuring machine has an extremely large measuring range, which is characterized by excellent access and great mobility. Highest accuracy and dynamics are guaranteed. Numerous variations and combinations of touch and scanning sensors are available.