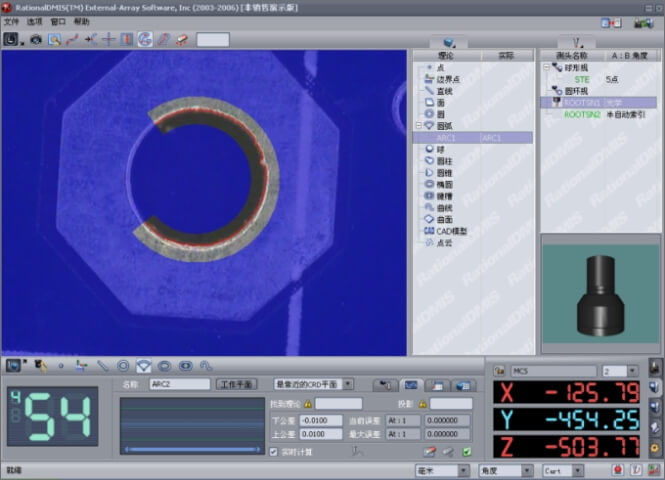

Professional CMM Software - RATIONAL-DMIS™

RationalDMIS is a new-generation coordinate measuring software, which is featured with various advantages, such as visualization, powerful function and high efficiency. It not only has been praised highly by experts in CMM industry since released into the market, but also wins the trust of customers.

With its powerful functions, including brief user-friendly software interface, unique drag & drop operation, seamless connection with CAD data, 100% graphical display from measuring to output report, and object-based quick programming tests, RationalDMIS is the most ideal option for manufacture industry and metrology industry.

Global Certification

ISO 22093:2003—(DMIS)

ISO 22093:2003—(DMIS)

DMIS2.1 ANSI/CAM-I 101-1990

DMIS2.1 ANSI/CAM-I 101-1990DMIS3.0 ANSI/CAM-I 101-1995

DMIS4.0 ANSI/CAM-I 104.0-2001

DMIS5.0 ANSI/CAM-I 105.0-2004

RationalDMIS has success fully passed the authentication of PTB, ISO, ANSI, DMIS and I++ DME, which prove that its accuracy, compatibility and reliability are recognized by the authority. RationalDMIS standards have been widely recognized among international industries and have become the standards for CMM industry globally!

- User-friendly Windows operation system.

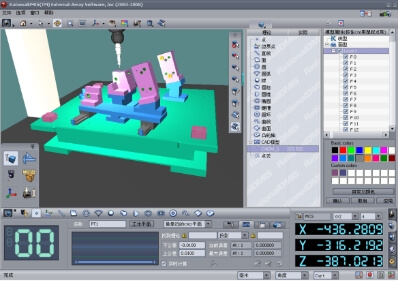

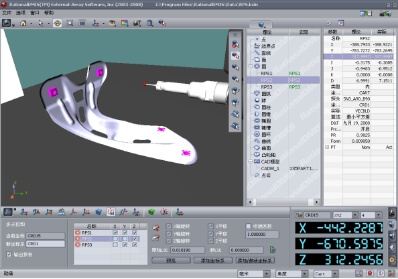

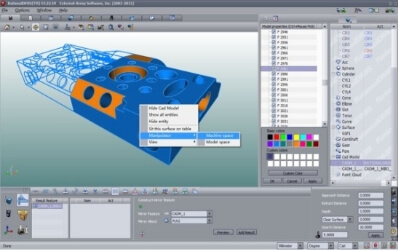

- Unique interactive 3D graphic engine.

- Computer-simulated CMM environment for off-line programming.

- Powerful, built-in analytical reporting capabilities.

- Built-in intelligence that automatically names features as they are measured.

- Sophisticated probe & part alignment management system.

- Straight forward tools for bi-direction linking of CMMs with any CAD system using either IGES or DMIS.

- Handling of 2D, 3D, wire-frame, and surfaced CAD files.

- Self-learning programming, easy to operate.

- Measurement of point, line, plane, circle, sphere, cylinder, cone, ellipse, curve, slot, surface, etc.

- Construction: project, bisect, intersect, angle between mirror, bestfit, move, parallel to, perpendicular to, offset and 3D position, capillarity, run out, etc.

- Measuring for sheet and metal, the thickness compensation.

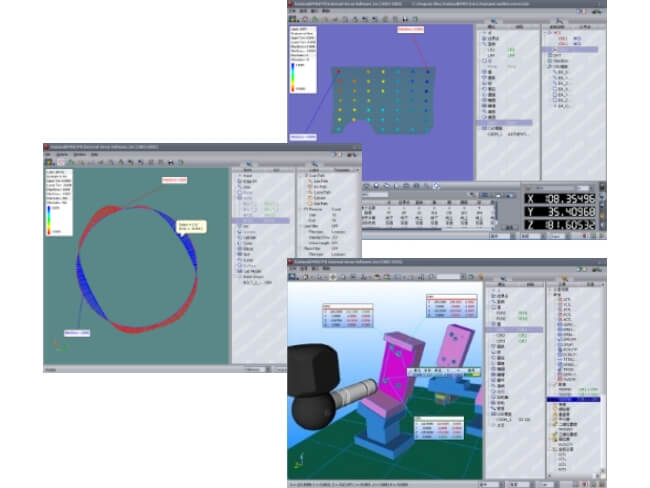

- Integrated TP-Scan point-point scanning and more ways scanning.

- Make curve by math model. Make curve or surface limit value and tolerance skeleton map directly.

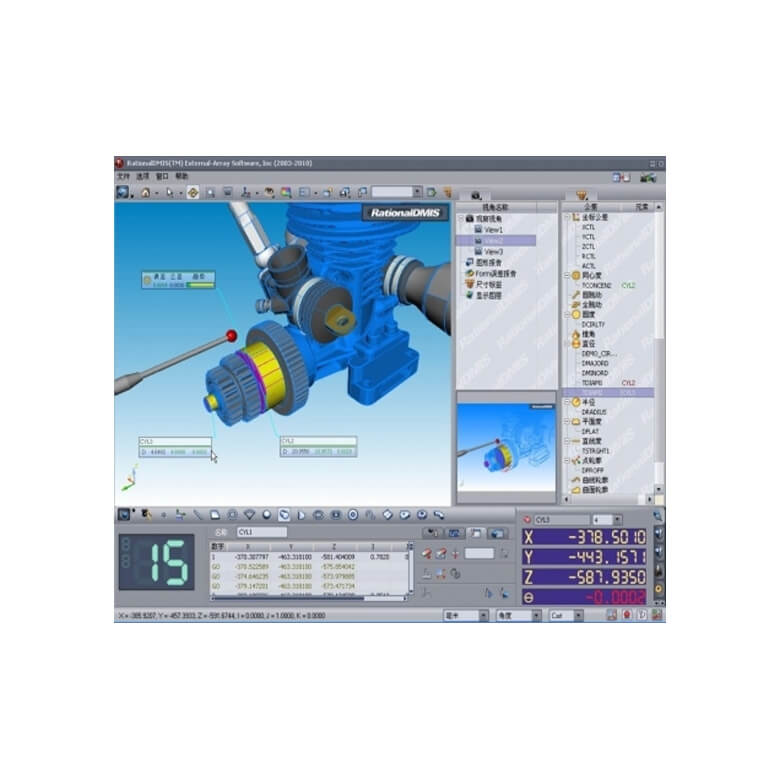

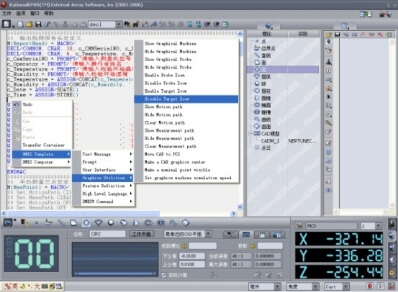

Intuitive, Brief Interface

- Supports Windows XP and Windows 7.

- Unique, intuitive, brief user interface.

- No pop-up window.

- No complicated input, verification process.

Simple, High-efficient Operations

- Real-time connection between graphic area, data area and operating area, simply “click with mouse” can identify all the features on CAD model, complete the quick editing of program, etc.

- Drag & drop maximally simplifies the operating process. Whether it is calibrating sensor, measuring feature, creating coordinate system, constructing feature, evaluating tolerance, or outputting reports, it can be completed by the drag & drop of mouse, which makes the operation much easier.

100% Graphical Display

- From create machine models → create sensor → calibrate sensor → create coordinate system →

measure parts → change sensor → construct feature → evaluate tolerance → output reports…

It is intuitive and clear!

100% DMIS

- DMIS 5.0 programming.

- DMIS self-learning program.

- DMIS format import/export.

- Graphical object-based quick programming.

- Support both online and offline programming.

- DMIS Chinese display, built-in DMIS program.

- Chinese-English quick translation.

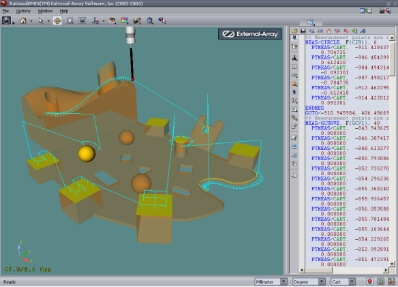

Seamless Connection with CAD Data

- Support IGES, STEP, DXF.

- Support Proe, UG, CATIA, ParaSolid direct interface.

- Read, edit CAD colors and layers.

- Automatically identify nominal CAD features: point/line/plane feature.

- Automatically find out nominal features and perform real-time comparison with nominal features.

- Quick CAD grid point measuring, CAD mirror image and CAD cutaway view.

Intelligent Measuring

- Anti-collision measuring, path preview and real-time simulation.

- Intelligent measuring: automatically identify the feature type based on the measuring point and location.

- Intelligent path planning: automatically create optimal measuring path.

- Dependence testing: identify whether the coordinate system and sensor are correct under current status.

- Rational shortcut panel: provide one shortcut window to quickly create coordinate system/construction/tolerance, etc.

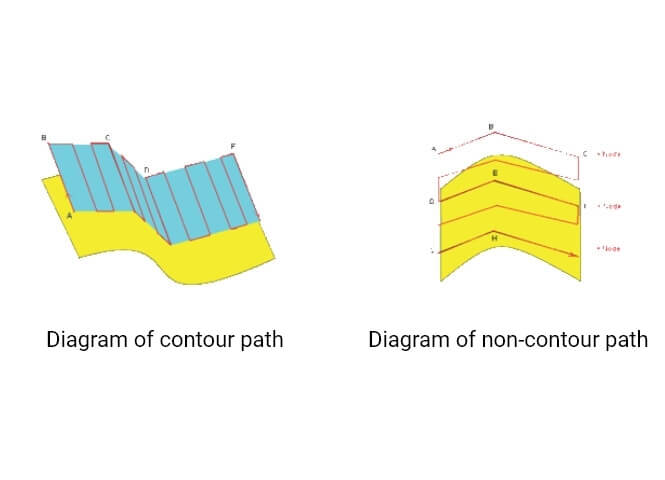

Continuous Scanning

- Support SP25, SP600, SP80...

- Support WPC triggered continuous scanning.

- Support REVO high-speed five-axis linkage scanning.

- Filtering function: filter the burr and disturbance during scanning.

- Support the non-contact quick scanning of line laser.

- Support Renishaw sensor changer.

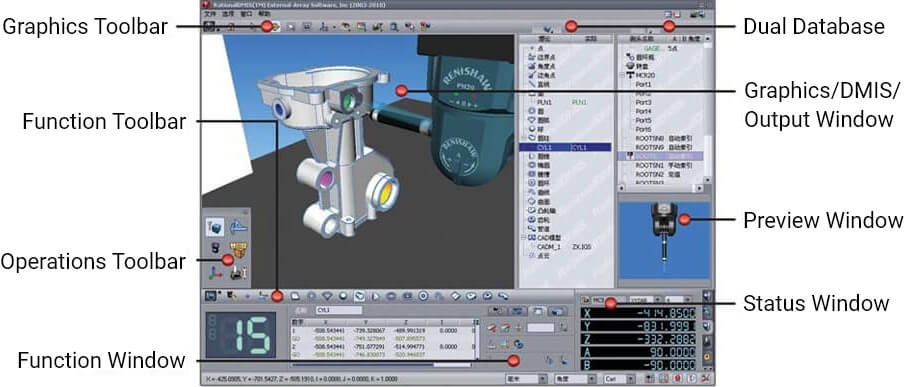

Various Methods to Create Coordinate System

- Coordinate system alignment of various complicated work piece.

- Quick 3-2-1 alignment.

- Quick CAD aligning work piece.

- RPS alignment.

- Multi-point fitting, Bestfit fitting.

- Iteration alignment (align work piece of free-form surfaces).

Powerful Construction Functions

- Satisfy various construction demands.

- CAD mirror, various geometrical features mirror.

- Intelligently and quickly fitting new features.

- Quickly construct limits.

- Feature array copy, rotation copy.

- Work piece deviation, material compensation.

Complete Quick Tolerance Evaluation

- In accordance with various standards: GB/ISO/ANSI/DIN/AGMA

- Evaluate various tolerances:

Distance/Angle/Angularity/Perpendicularity/Parallelism/Position/Cylindricity/Concentricity/CircularRunout/TotalRunout/Circularity/Cone Angle/Diameters/Radius/Flatness/Straightness/Point Profile/Curve Profile/Surface Profile/Symmetry/Width - Label the error of feature dimensions graphically.

- Support max entity MMC, min entity LMC, RFS.

- Quickly evaluate the tolerances of single feature, quickly copy and evaluate features of the same type.

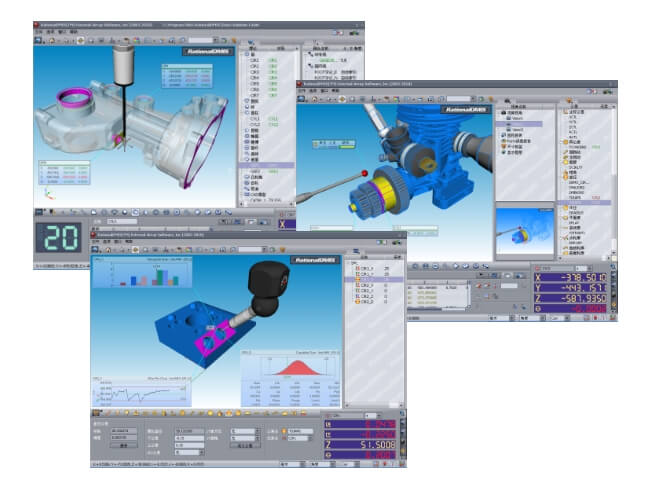

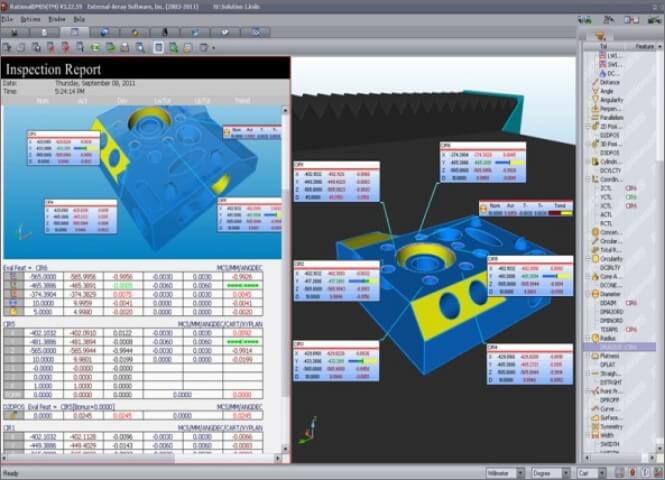

Diversified Output Reports

- Traditional text report output.

- Graphic output.

- SPC data statistics and analytical report.

- All kinds of form error report.

- Output of various forms, including HTML, EXCEL, PDF, etc.

- Import, edit user-defined output templates.

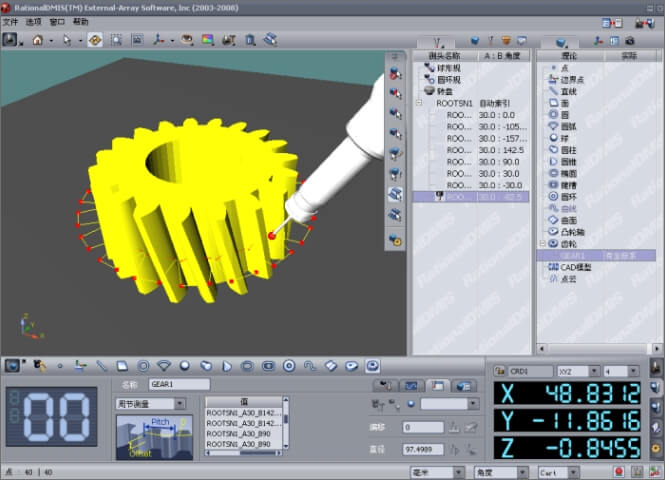

Gear Module

Used to measure the involute gear of cylinder, including internal straight gear, external straight gear and helical gear.

Automatically construct gear CAD based on the design parameters.

Automatically construct gear CAD based on the design parameters.

Gear Path/Lead/Profile Measure

Gear Path/Lead/Profile Measure

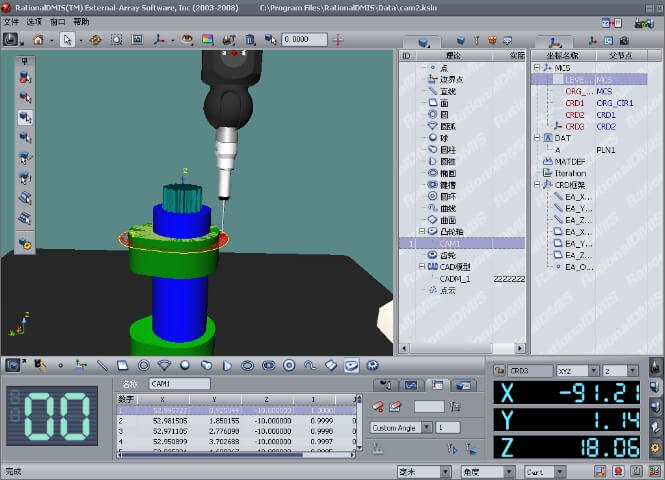

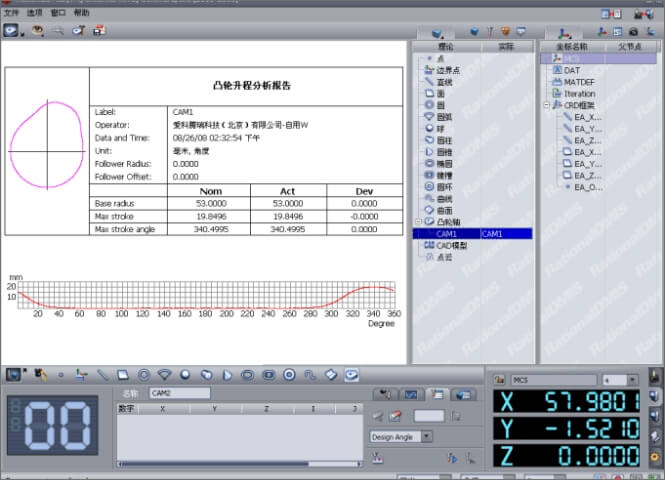

Cam Module

Used to analyze cam/camshaft.

Cam shaft.

Cam shaft.

Cam report.

Cam report.

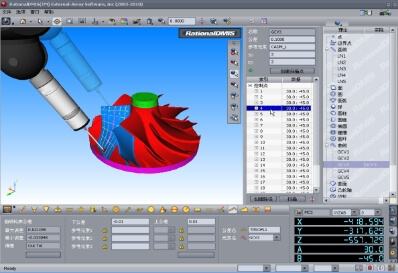

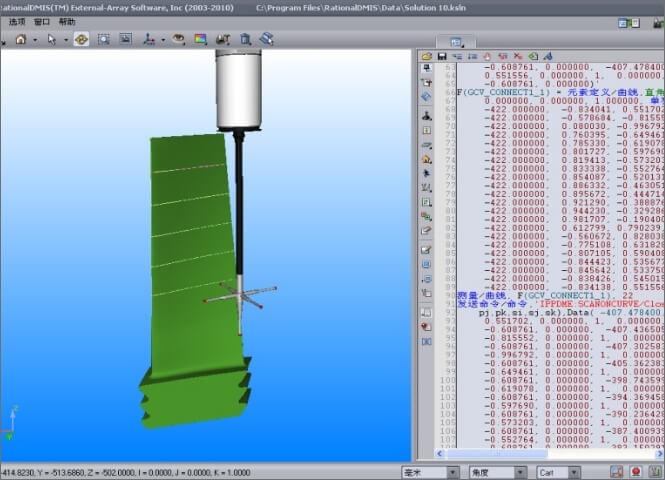

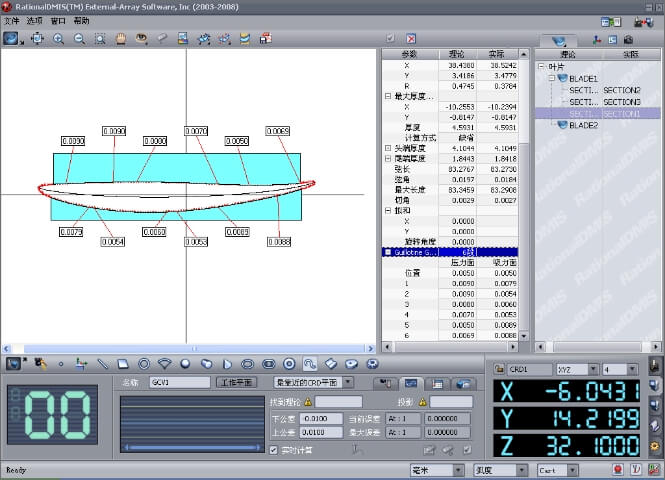

Blade Module

Used to measure and analyze aviation blade, nuclear power blade.

Measure Blade.

Measure Blade.

Evaluating Blade’s parameter.

Evaluating Blade’s parameter.

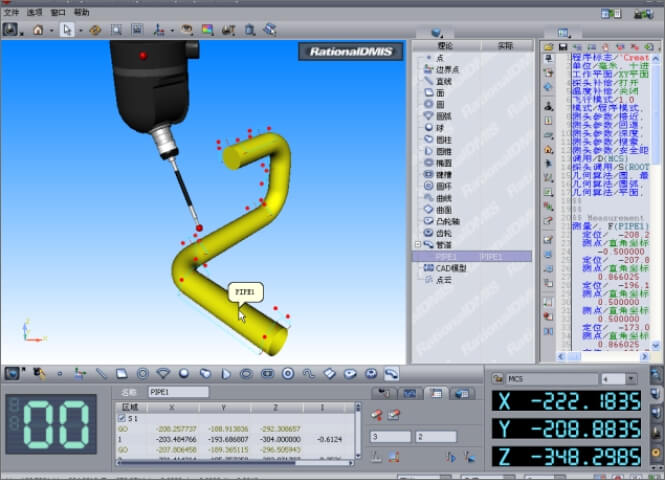

Pipe Module

Used to test and analyze the automobile pipe, oil pipe.

View and save the graphic pipe data in output report.

View and save the graphic pipe data in output report.

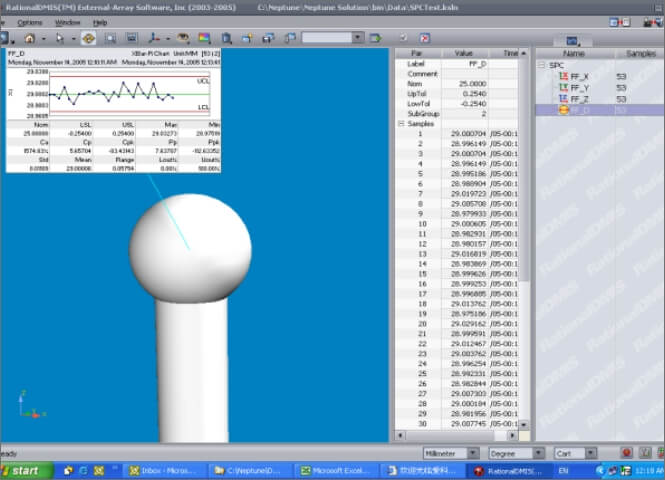

SPC Module

Used for the statistics and analysis of product quality.

CCD Module

Used for the analytical testing, complex measuring of graphics.

CCD calibration and complex calibration.

CCD calibration and complex calibration.

Complex calibration: Make sure that the data of CCD and triggered sensor area combined into the same coordinate system.

Complex calibration: Make sure that the data of CCD and triggered sensor area combined into the same coordinate system.

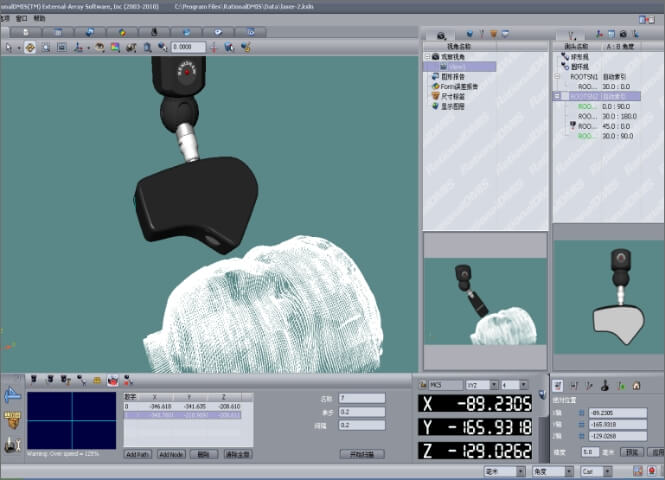

Laser Scanning Module

Usually used in high-speed, high-precision reverse engineering.

Measuring angles and stitching trimming of scanning data automatically.

Measuring angles and stitching trimming of scanning data automatically.

- User-friendly Windows operation system.

- Unique interactive 3D graphic engine.

- Computer-simulated CMM environment for off-line programming.

- Powerful, built-in analytical reporting capabilities.

- Built-in intelligence that automatically names features as they are measured.

- Sophisticated probe & part alignment management system.

- Straight forward tools for bi-direction linking of CMMs with any CAD system using either IGES or DMIS.

- Handling of 2D, 3D, wire-frame, and surfaced CAD files.

- Self-learning programming, easy to operate.

- Measurement of point, line, plane, circle, sphere, cylinder, cone, ellipse, curve, slot, surface, etc.

- Construction: project, bisect, intersect, angle between mirror, bestfit, move, parallel to, perpendicular to, offset and 3D position, capillarity, run out, etc.

- Measuring for sheet and metal, the thickness compensation.

- Integrated TP-Scan point-point scanning and more ways scanning.

- Make curve by math model. Make curve or surface limit value and tolerance skeleton map directly.